Forklift Safety Regulations Canada

Understanding safety regulations in Canada is critical to protecting employees, preventing costly accidents, and maintaining regulatory compliance. With a complex framework of federal and provincial laws complemented by detailed Canadian Standards, employers and operators must clearly understand their responsibilities and best practices. This post breaks down the key regulations, standards, roles, and safety requirements you need to know to create a safe, productive work environment and avoid serious penalties. Whether you’re an employer, supervisor, or forklift operator, this guide will help you navigate the essential aspects of forklift safety in Canada.

If you are looking for comprehensive forklift safety training, we can help. Contact us today to get the training you need to stay safe.

Key Takeaways

Understanding Canadian Safety Regulations

Canadian workplace safety is governed by federal and provincial laws aiming to protect workers’ health and safety.

The Canadian Centre for Occupational Health and Safety (CCOHS) leads national efforts in education and compliance.

Jurisdiction depends on the industry: federally regulated workplaces follow the Canada Labour Code; most others follow provincial/territorial OHS laws.

Compliance improves safety culture and avoids costly fines, legal action, and insurance issues.

Canadian Standards That Govern Forklift Safety

CSA B335-15 is the national standard for forklift safety, covering operator training, inspections, and maintenance.

Provinces incorporate CSA standards into their OHS laws with some regional variations.

Employers must ensure proper training, maintenance, and hazard assessments to prevent incidents.

Roles & Duties: Who Is Responsible?

Employers hold primary responsibility for safe workplaces, training, and equipment upkeep.

Supervisors enforce safety protocols, supervise operators, and maintain training records.

Workers must operate forklifts safely, report hazards, and wear PPE.

Key Forklift Safety Requirements

Only certified and trained operators may operate forklifts.

Daily pre-shift inspections are mandatory to identify and remove unsafe equipment.

Operators must adhere to load limits, speed limits, and use safety devices such as seatbelts and horns.

Clear signage and traffic controls are essential in forklift operation areas.

Benefits of Compliance

Reduces workplace injuries, accidents, and downtime.

Avoids fines, legal penalties, and insurance complications.

Builds employee trust, morale, and improves productivity.

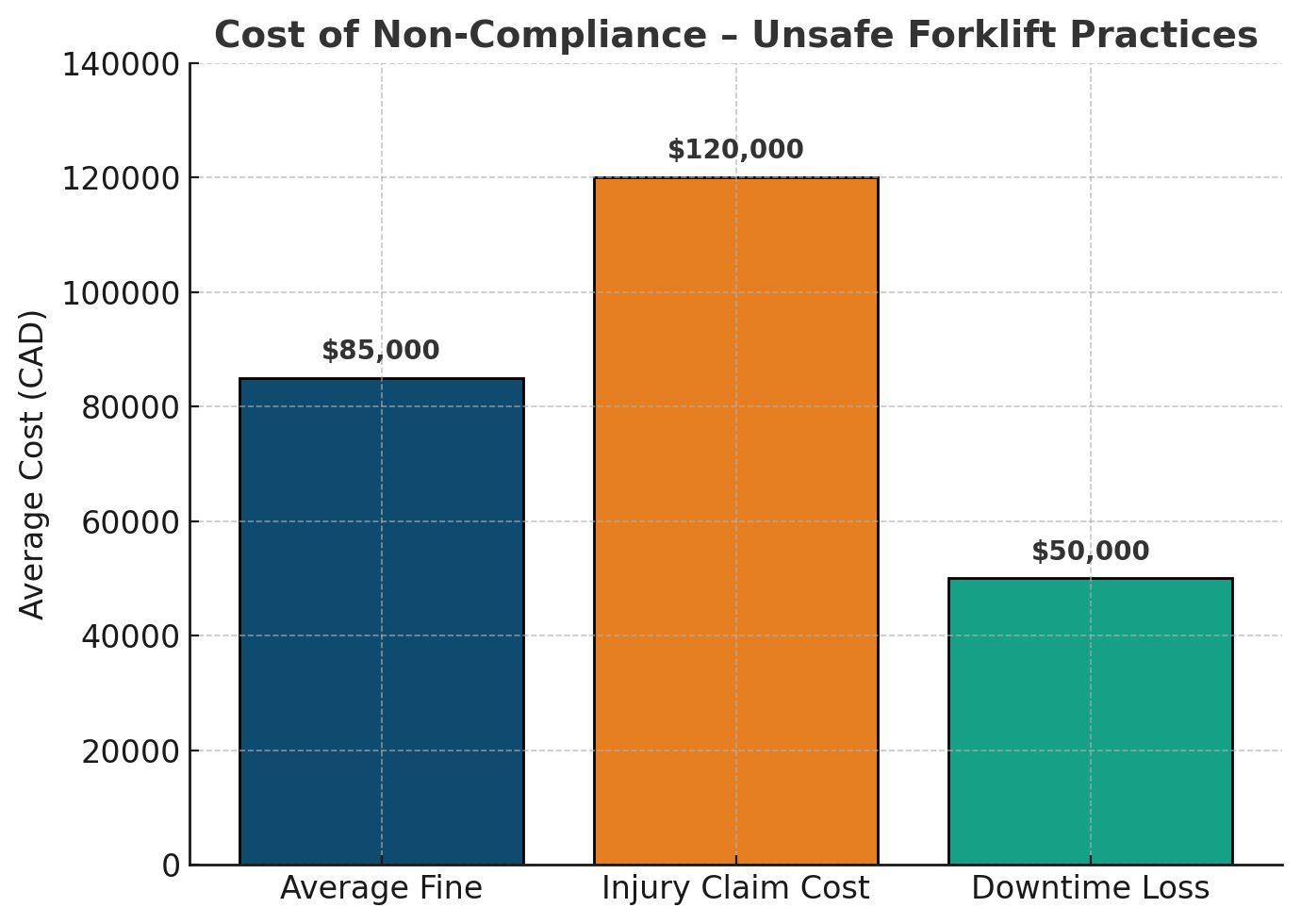

Penalties for Non-Compliance

Fines can be substantial, including multi-million dollar penalties and possible jail time for serious violations.

Notable recent cases highlight the severe consequences of unsafe forklift practices.

Ignorance of the law is not a defence; proactive compliance is crucial.

Keeping Up to Date

Regular refresher training and ongoing education are vital to maintain compliance.

Subscribe to updates from federal and provincial OHS authorities.

Work with certified safety consultants and forklift dealers to stay current on regulations and best practices.

Forklift Safety Regulations Canada

1. Understanding Canadian Safety Regulations

Canadian workplace safety is governed by a strong regulatory framework with the goal of protecting the health and well-being of workers. Employers, regardless of whether they are working on a provincial or federal level, must be knowledgeable and compliant with relevant safety regulations in order to avoid fines, maintain insurance, and offer a safe work environment.

Canada's Occupational Health and Safety (OHS) Framework

Canada's OHS system is a combination of federal, provincial, and territorial laws designed to protect employees against occupational injury and illness.

OHS legislation is designed to prevent occupational injury and illness by providing adequate training, supervision, and safety procedures. The legislation outlines the responsibilities of employers, supervisors, and employees.

The Canadian Centre for Occupational Health and Safety (CCOHS) provides national leadership for workplace health and safety and makes educational materials, advice, and compliance tools available.

Federal or Provincial/Territorial Jurisdiction

Workplace safety responsibility is shared with federal and provincial/territorial governments, depending on industry and employment type.

Industries regulated by the federal government, such as air transportation, banking, telecommunications, and interprovincial trucking, are governed by the Canada Labour Code, Part II.

Most other workplaces (around 94%) are provincially or territorially regulated. Each jurisdiction has its own OHS law, though most adhere very closely to national standards.

Provinces often reference the CSA B335-15 Safety Standard for Lift Trucks or similar guidelines in their powered industrial truck legislation, e.g., forklifts.

Importance of Compliance

OHS legislation compliance is not only required for financial and legal reasons, but also to enhance a culture of safety.

Non-compliance can lead to severe financial and legal repercussions. Stop-work orders, fines, and even criminal action can be invoked on failure in a serious incident or audit.

Insurance can be forfeited in the absence of compliance with regulations on safety. Insurers can deny claims where negligence or regulatory non-compliance is detected.

Employee morale, health, and productivity are all increased when a company demonstrates its dedication to safety. Safe workplaces recruit and retain quality employees and reduce downtime due to accidents.

2. Canadian Standards That Govern Forklift Safety

Both national regulations and regional Occupational Health and Safety (OHS) rules govern forklift safety in Canada. Whichever is applicable, the employer must comply with the relevant laws to guarantee a safe working environment.

CSA B335-15: Safety Standard for Lift Trucks

The CSA B335-15 standard, published by the Canadian Standards Association (CSA Group), is a national standard for the safe use, maintenance, and training related to lift trucks (forklifts).

The standard delivers mandatory requirements for operators' training, evaluation, and recertification. The standard is geared towards hands-on training and regular observation of performance.

CSA B335-15 also includes standards for the following:

Regular inspection

Preventative maintenance

Record-keeping

These operations are designed to prevent mechanical failure and ensure long-term equipment reliability.

The employer must put in place hazard assessments and adopt safety practices particular to their operation. These assessments should be recorded and reviewed from time to time.

Occupational Health and Safety Regulations (Provincial/Territorial)

Every Canadian territory and province has its own Occupational Health and Safety law that generally references CSA B335 or equal standards for the operation of a forklift.

Here are some examples of standards used by various provinces:

Alberta: Occupational Health and Safety Code

British Columbia: Workers’ Compensation Act and OHS Regulation

Quebec: CNESST Quebec Safety Act

Manitoba: Workplace Safety and Health Act

Saskatchewan: The Occupational Health and Safety Regulations

Nova Scotia: Occupational Health and Safety Act

These provincial codes prescribe employer duties for operating forklifts, workplace inspections, and measures to prevent injury.

Canada Labour Code Part II (Federal Workplaces)

For federally regulated industries like railways, banks, airports, and interprovincial trucking, forklift safety falls under Canada Labour Code Part II.

The Code stipulates that employers must provide adequate training, supervision, and maintenance of any equipment used in the workplace.

Regular hazard identification and recommended improvements are mandatory for workplace committees where appropriate.

Major Safety Requirements in Every Jurisdiction

Regardless of the jurisdiction, employers must comply with the following basic safety requirements:

Operator Training and Certification: All forklift operators shall be trained and tested in accordance with CSA B335-15 or provincial equivalents. Certifications need to be updated from time to time.

Maintenance and Equipment Inspection: Forklifts must be checked before every shift and serviced according to manufacturer guidelines and CSA regulations.

Hazards Identification in the Workplace: Identification of hazards for forklift operation is the employer's responsibility, and controls are applied.

The above safety requirements need to be reevaluated every time there is a change in work processes.

3. Who Is Responsible? Roles & Duties

Canadian Occupational Health and Safety (OHS) legislation is based on the Internal Responsibility System (IRS). The IRS accepts that all members of the workplace, employers, supervisors, and employees, are accountable for health and safety. Each position has clearly defined responsibilities under federal and provincial legislation.

Employers

Employers bear the greatest responsibility and need to make sure that their environment of work is safe and legal.

Operator Training: Employers need to give adequate training to forklift operators so that it complies with the CSA B335-15 standard or provincial regulations as applicable. The training must be both theoretical and practical.

Equipment Maintenance: They must make sure all equipment is properly maintained, inspected regularly, and safe to use. Maintenance records and inspection lists must be current.

Safety Policies: Employers must develop and establish workplace safety policies and procedures. They must also supply safety gear and protective attire where required.

Supervisors

Supervisors are the on-site enforcers of safety protocols. They are individually responsible for monitoring that procedures are being followed and that workers are being supervised.

Monitor Employees: Supervisors need to monitor employee work patterns and correct unsafe behavior at the moment. Supervisors are typically the initial barrier to preventing workplace accidents.

Keep Records: They need to monitor that forklift operators drive equipment only if they are certified and trained. Supervisors need to keep records of training and monitor re-certification dates.

Review Safety Procedures Periodically: Supervisors should also explain safe working procedures and modifications to employees periodically. Among the duties are toolbox talks, safety meetings, and check-ins.

Workers

For example, forklift operators should also be proactively responsible for their and other people's safety.

Operate Equipment Safely: Staff must operate forklifts and other powered equipment safely, consistent with all training and workplace procedures. Careless or unauthorized use is a violation of OHS standards.

Inform of Hazards: They must inform a supervisor immediately of hazards, unsafe conditions, or defective equipment. Reporting early avoids accidents and enables quick repairs.

Wear Proper PPE: Staff must wear appropriate personal protective equipment (PPE) and receive necessary safety training. Failure to do so puts the individual and coworkers at risk.

4. Key Forklift Safety Requirements

Operating a forklift incorrectly can cause severe safety issues, and therefore, strict rules and regulations are in place across Canada. Whether on a construction site, warehouse floor, or an industrial facility, employers and operators must follow set safety protocols to prevent injury, property destruction, as well as legal penalties.

Only Certified and Trained Operators Are Authorized to Operate Forklifts

Only those workers who successfully completed certified forklift training and certification can drive powered industrial trucks. This is mandated in the CSA B335-15 workplace safety standard and is federally and provincially legislated.

Forklifts Must Be Inspected Daily Prior To Use

A daily pre-shift inspection must be done prior to using a forklift. The inspection includes, but is not limited to, checking the following:

Brakes

Tires

Steering

Forks

Fluid levels

Warning devices

Damaged or unsafe equipment must be taken out of service for repair. Inspectors should document the inspection and may be required to do so in audits.

Load Limits, Speed Limits, and Safe Operating Procedures

Load Limits: Operators need to comprehend and obey the forklift's rated load weight (capacity) and never operate above it. Overloading can cause tipping and mechanical failure.

Speed Limits: Speed limits should be posted and observed in both indoor and outdoor operating spaces. Operators must reduce speed when turning corners, reversing, or entering intersections.

Safe Operating Procedures: Safe procedures like backing up with unobstructed loads and having a spotter in blind areas must be executed at all times.

Wearing Seatbelts, Horns, and Other Safety Devices

Seatbelts: Seatbelts are required to be worn by all forklift operators to avoid ejection in case of a tip-over. Seatbelts must be worn under the majority of provincial OHS codes.

Horns: The horn should be activated when approaching intersections, doorways, and corners. Warning pedestrians and other operators to avoid collisions.

Other Safety Devices: All other safety equipment, such as backup alarms, lights, and mirrors, must be in good working order and operating effectively.

Clear Signage and Traffic Control in Shared Spaces

Clear Signage: Areas where forklifts operate must have pedestrian walkways and traffic routes clearly marked. Strategically placed signage maintains pedestrian traffic isolated from mobile equipment.

Mirrors, warning lights, stop signs, and speed limit signs must be installed on busy roads. These controls must be used in warehouses, loading docks, as well as in factory floors.

5. Benefits of Compliance

Following federal and provincial occupational health and safety (OHS) legislation and Canadian Safety Standards for forklifts, such as CSA B335 Safety Standard for Lift Trucks, is in the best interest of employers and employees. It is not only the law, but a sound business decision that encourages a healthier, more productive work environment.

Here is a breakdown of the advantages of following forklift safety regulations in Canada.

Reduced Workplace Injuries and Accidents

Adherence to forklift safety regulations greatly reduces the chances of accidents caused by improper use, faulty maintenance, or dangerous operations. Reduced accidents means less workflow disruption and a safer environment for everyone on site.

Fewer Breakdowns and Operation Disruptions

Trained operators and properly maintained equipment ensure seamless forklift operation and dependability. Fewer accidents and breakdowns mean more consistent productivity and less unplanned downtime.

Legal Shield from Penalties and Fines

Compliance with OHS legislation and CSA regulations shields businesses from costly legal consequences. Avoiding non-compliance will help you maintain the good reputation of your company as well as minimize regulatory focus.

Lowered Insurance Premiums and Claims

A sound history of safety can lead to lower insurance premiums. Fewer accidents mean fewer claims, keeping your insurance costs low and under control.

Enhanced Employee Morale and Credibility

Your employees will be more at ease in a business that prioritizes safety. Demonstrating commitment to safety fosters trust, commitment, and a healthy company culture.

6. Penalties for Non-Compliance

It is not only about minimizing the risk that awareness of and compliance with forklift safety standards is about, but it is also about avoiding serious legal and financial consequences. Employers and supervisors must be reminded that ignorance of the law is no excuse for non-compliance.

Fines under Provincial Legislation and Legal Sanctions

Canadian provincial safety agencies take forklift safety violations seriously, and fines can be substantial:

In Ontario, under the Occupational Health and Safety Act (OHSA), the following penalties can be applied for non-compliance:

Corporations: Corporations may be fined up to $2 million,

Directors: Directors or officers may be fined up to a maximum of $1.5 million in fines and/or 12 months’ incarceration.

Others: Other individuals may be fined up to $500,000 and/or be put in prison for up to one year.

Here are a few examples of actual incidents that resulted in workplace accidents and resulting fines:

Janco Steel Ltd. in Stoney Creek was fined $200,000 (plus 25% victim surcharge) when, in 2022, an employee was fatally struck by an industrial forklift due to unsafe work practices.

Performance Finishing & Fabrication Inc. was fined $110,000 (plus surcharge) after a fatal forklift incident due to failing to secure a load according to Regulation 851, section 25 (1)(c) of OHSA.

Geerlinks Building Centre (Home Hardware) was fined $70,000 (surcharge included) after an uncertified driver struck a co-worker with a forklift.

Sobeys Capital Inc. was fined $80,000 after a forklift operator injured his leg in an accident involving poorly maintained dock equipment.

Why Compliance Is Non-Negotiable

Even where gaps in training or procedure are accidental, legal systems hold businesses accountable. The stance that "ignorance of the law is not a defence" reinforces that businesses need to actively seek education and stay compliant.

Aside from the fines themselves, breaches levy additional victim surcharges (typically 25%), reputational damage, potential judicial action by victims or worse, criminal prosecution and incarceration.

Takeaway for Employers, Supervisors & Employees

Enforcement of forklift safety regulations is not voluntary. Lack of knowledge or disrespect of the law can result in devastating harm, huge fines, and lasting reputational damage. Invest upfront in training, inspections, and safety initiatives rather than waiting for enforcement to force your hand.

7. Keeping Up to Date

Forklift standards and regulations can change over time, and staying current is essential to maintaining compliance and protecting your workers. Employees, supervisors, and employers all need to be proactive in keeping current with both federal and provincial requirements.

Encourage Ongoing Safety Training and Repeat Courses

Ongoing safety training informs operators and supervisors of recent regulations, safe operating procedures, and equipment developments.

Refresher training enhances essential skills, removes harmful habits, and ensures workers are comfortable operating forklifts safely.

Subscribe to Provincial and Federal OHS Authority News

Subscribe to e-mail notifications or newsletters from authorities such as Employment and Social Development Canada (ESDC), Ontario Ministry of Labour, Immigration, Training and Skills Development, or any other provincial OHS organizations to be sure you receive timely updates.

By staying connected with these sources, your workplace can keep pace swiftly with new regulations, safety bulletins, or enforcement programs.

Seek Advice of Certified Safety Consultants or Forklift Dealers for Compliance

Collaboration with certified safety consultants provides professional guidance regarding compliance with or exceeding current safety guidelines.

Compliance audits, operator training, and safety equipment recommendations unique to your industry are normally provided by quality forklift dealers.

8. Comprehensive Resources: CSA Standards and Government Regulations for Forklift Safety in Canada

To help you meet all legal and technical requirements for forklift safety, here are essential standards and regulatory resources from CSA and Canadian federal and provincial authorities.

Key CSA Standards for Forklift Safety

CSA B335: Safety Standard for Lift Trucks

Covers design, manufacture, inspection, maintenance, and safe operation of lift trucks, including forklifts.

CSA Z1000: Occupational Health and Safety Management

Framework standard for workplace health and safety programs.

CSA Z151 : Safety Standard for Scaffolding and Other Access Equipment

Relevant for elevated work platforms or forklift attachments.

Federal Regulations

Canada Labour Code - Part II (Occupational Health and Safety)

The federal code governing workplace health and safety in federally regulated industries includes forklift safety requirements.

Workplace Hazardous Materials Information System (WHMIS)

Governs hazardous materials that forklift operators may encounter.

Provincial Occupational Health and Safety Authorities & Forklift Safety Links

Alberta Occupational Health and Safety

Forklift Safety - OHS Alberta

British Columbia WorkSafeBC

Forklift Safety - WorkSafeBC

Manitoba Workplace Safety and Health

Forklift Safety - Manitoba

New Brunswick Occupational Health and Safety

Forklift Safety - NB OHS

Newfoundland and Labrador OHS Division

Forklift Safety - NL OHS

Nova Scotia Occupational Health and Safety

Forklift Safety - NS OHS

Ontario Ministry of Labour, Immigration, Training and Skills Development

Forklift Safety - Ontario MOL

Prince Edward Island OHS

OHS PEI

Quebec Commission des normes, de l'équité, de la santé et de la sécurité du travail (CNESST)

Forklift Safety - CNESST

Saskatchewan Ministry of Labour Relations and Workplace Safety

Labour Relations and Workplace Safety SASK

Disclaimer: This post is intended for general informational purposes only and should not be considered legal or professional advice. Regulations and standards related to forklift safety may change and can vary by jurisdiction. Always consult official government sources, regulatory bodies, or qualified safety professionals to ensure compliance with the most current and applicable laws and standards.

Why Choose ForkliftHub for Forklift Training?

Forklift training is convenient, easy, and efficient with ForkliftHub. We connect you with expert trainers and provide flexible schedules to accommodate your needs. Whether you're a single individual in need of certification or an employer in need of certifying employees, we can help.

Experienced Professionals with Field Experience

We connect you with professional trainers with extensive real-world industry experience in your area. Our instructors are familiar with actual job site conditions and safety issues. You'll learn hands-on knowledge that is beyond the textbook.

Certification for All Types of Forklifts

ForkliftHub provides certification for all categories of forklifts. Whether you're driving a counterbalance, reach truck, or rough terrain forklift, we have you covered. Training is equipment-specific to the equipment you'll be operating.

Group and Individual Training Options

We offer flexible training options to accommodate your situation. Enroll in individual certification or arrange training for your entire crew. We make compliance easy for individuals and companies alike.

Convenience of On-Site and Off-Site Training

Choose the site where training is most convenient for you. We can bring trainers to your work location or arrange training at a convenient facility near you. This convenience saves time and gets operators trained at the location where they will operate.